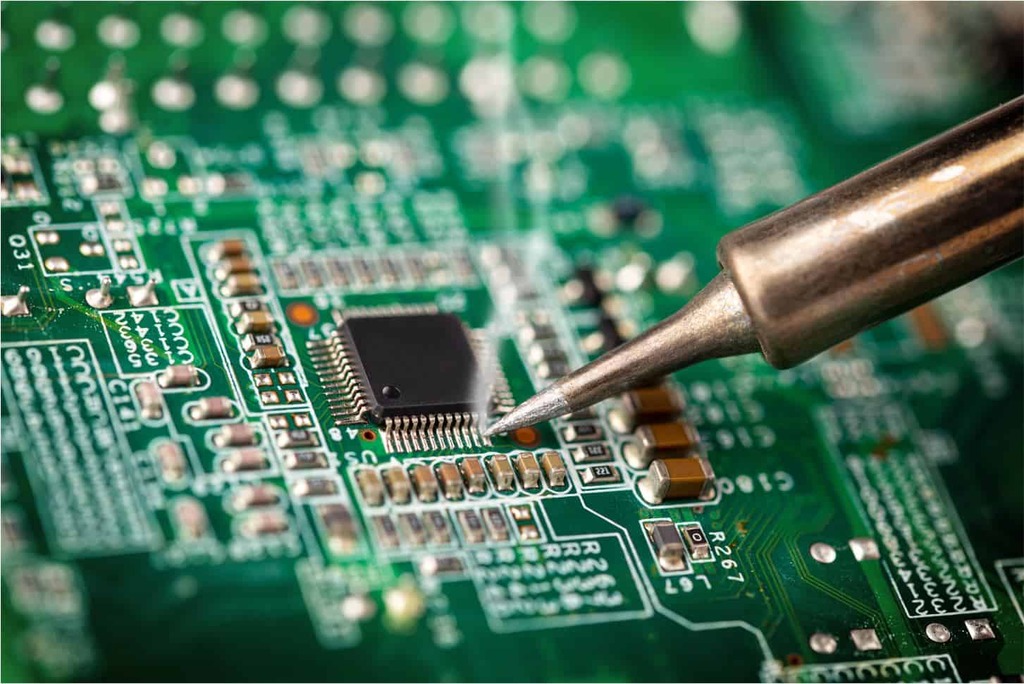

Rework and soldering are crucial skills for the production of electronics.

In both mechanical support (holding parts of an assembly together) and electrical support (creating necessary electrical connections within a circuit), soldering is essential. Reworking, which often involves desoldering and re-soldering of surface-mounted electronic components (SMD), is also a crucial step for the refinishing operation or repair of an electronic printed circuit board (PCB) assembly. These procedures can be difficult, though. There is always opportunity for development and picking up new skills, whether you are a novice or an expert technician. You can improve your soldering and rework skills and procedures by using the advice and best practices in this article. (The editors of LinkedIn have revised this section based on member comments.)

Pick the appropriate equipment and supplies.

Choosing the appropriate equipment and materials for the task is the first step in honing your soldering and rework abilities and procedures. A good soldering iron with the proper tip, a soldering station with temperature and power adjustments, a solder sucker or wick for removing excess solder, a pair of tweezers and cutters for handling components, and a magnifying glass or microscope for checking your work are all necessary. To maintain strong solder junctions and prevent corrosion and contamination, you will also require the appropriate type, size, and cleaning supplies.

Prepare your work area and components

You must take the time to set up your work environment and components before you begin in order to improve your soldering and rework skills and approaches. Make sure your workspace is tidy, well-ventilated, well-lit, and has a solid surface that can withstand heat. To prevent burns, gases, and spills, be sure to put on safety gear including gloves, goggles, and a mask. To get rid of any grime, grease, or oxidation that can compromise the soldering quality, clean the tip of your soldering iron, as well as any of its parts, using alcohol or a specialized cleaner. To enhance heat transfer and wetting, you must also pre-tin your soldering iron tip and component surfaces with a tiny layer of solder.

Follow the proper soldering and rework techniques

Making sure that you use the appropriate soldering and rework procedures for the type of component and joint you are working on is another important step in honing your soldering and rework abilities and approaches. Apply the solder to the joint, not to the tip of the soldering iron, after concurrently heating the component and the pad or wire. Additionally, be sure you are using the proper ratio of solder, flux, and heat to produce a junction that is bright, trustworthy, and smooth. A joint should not be overheated, moved, or touched until it has cooled and solidified. Use a solder sucker or wick to remove extra solder if you need to rework or remove a component or joint.

Practice and learn from your mistakes

Test your work for functionality and quality after practicing your soldering and rework techniques on various types of components, boards, and circuits. Check your work for flaws like cold joints, bridges, shorts, or openings and figure out their causes and fixes. If you do make a mistake, be sure to look into what exactly you did to prevent repeating the error. Above all, take advantage of any missteps as teaching moments.

Seek feedback and guidance

Seeking advice and input from others is the fifth stage to enhancing your soldering and rework abilities and methods. To advance your soldering and rework abilities and procedures, you will need to seek out guidance and pointers from more seasoned technicians, teachers, or mentors. The best practices and techniques for soldering and rework must also be demonstrated and explained through online tutorials, videos, or courses. You should also sign up for online forums, communities, or organizations where you can show off your work, get advice from others, and ask questions.

Keep up with the latest trends and innovations

You can enhance your soldering and rework abilities by staying current with the most recent trends and developments in the electronics manufacturing industry. Explore new equipment, methods, or solutions that can help you produce better results, efficiency, or quality in your soldering and rework jobs. Keep up with the latest technology, materials, standards, and laws that have an impact on the soldering and rework operations.

Here’s what else to consider

If you have any examples, tales, or insights that don’t fit in any of the other areas, please share them here. What other comments do you have?